Trouble-shooting for

cooling towers:

|

|

|

Troubleshooting |

||

|

|

|

Trouble |

Cause |

Remedy |

Motor Stoppage |

Electric Blackout. Fuse Burn Out. Insufficient Switch Capacity. Bad Switch Contact. |

Contact Power Co. 2 Get Proper Fuse. Change the Proper Switch. Adjust Contact. |

Sudden Lowering of Motor R.P.M. |

Bad Star-Delta Contact. Too Heavy Loads. Lowering of Voltage. |

Adjusts Contact. Lighten to Proper Load. Consult Power Company. |

Fan Stoppage |

Bad Bearing |

Exchange Bearing |

|

|

|

|

|

|

Temperature Rise |

||

|

|

|

Trouble |

Cause |

Remedy |

Motor Temperature Rise |

Too Heavy Load. Lowering of Voltage. High Surrounding. |

Lighten Load to Proper Level. Consult Power Company. Send Out to Repair Shop. |

|

|

|

Rise in Water Temperature |

||

|

|

|

Trouble |

Remedy |

|

Water Flow Above Specified Flow |

Correct Flow Rate. |

|

Air Flow Below Specified Flow. |

Adjust Blade Angles Check and Clean Jali. |

|

Load Higher than Design |

Adjust Load to correct Flow Rate. |

|

Fills Chocked or Coated |

Clean/Replace Fills. Use Proper Water Quality (Make up) |

|

Fresh Air Intake not sufficient or area sufficient or area near tower not as specified. |

Improve Ventilation and Ensure Exhaust air does not get recycled. |

|

Water Bypassing Fills. |

Check Sprinkler Head and Pipe Leakages. |

|

Sprinkler Jammed/Water not being Sprinkled and Distributed. |

Repair Sprinkler and Distribution System. |

|

|

|

|

Water Flow Less |

||

|

|

|

Trouble |

Remedy |

|

Filters Chocked |

Clean Water Filters |

|

Sprinkler Pipe Chocked |

Clean Pipes and Holes |

|

Level of Water Low in sump |

Adjust Float/Inlet Flow Proper Make-up |

|

Pump Small |

Replace to Correct Flow Volume |

|

Filters Chocked |

Clean Water Filters |

|

Sprinkler Pipe Chocked |

Clean Pipes and Holes |

|

Level of Water Low in sump |

Adjust Float/Inlet Flow Proper Make-up |

|

Pump Small |

Replace to Correct Flow Volume |

|

|

|

|

Noise & Vibration |

||

|

|

|

Trouble |

Remedy |

|

Fan Mounting Loose |

Tighten Mounting Bolts and Correct/Replace if needed. |

|

Fan Blocks Loose |

Tighten Blade in Hub |

|

Fan Unbalanced |

Rebalance and Adjust |

|

Motor Bearing Faulty |

Check and Grease or Replace Bearing on Motor |

|

Hub Mounting on Motor Shaft Loose |

Tighten and use end Plate and shims if required |

|

Many Parts Rubbing againt Tower Component |

Give Proper Clearance and Adjust/Align Components. |

|

|

|

|

Water Carry Over |

||

|

|

|

Trouble |

Remedy |

|

Sprinkler Rotation too Fast |

Adjust Sprinkler Angles as to Match the specified rotation |

|

Blocking of Filter |

Clean up any blockage part |

|

Defective Eliminator |

Renew Eliminator |

|

Sprinkler too high above fills |

Adjust as specified below |

|

25 M.M. FT –8 TO FT-30 |

||

50 M.M. FT-40 TO FT-80 |

||

75 MM. FT-100 AND UP |

||

|

|

|

Water Carry Over |

|

Every Day |

|

Vibrations Are Normal/Noise Normal. |

Water Distribution Proper. |

Fan Motor Current Normal. |

Inlet/Outlet Temperature Of Water Normal. |

|

Every Day |

|

Clean Inlet Jali To Remove Entrained Matter. |

Clean Inlet Water Filter. |

Clean Sprinkler / Nozzles If Chocked. |

Check Growth of Alger Etc. And Remove From Sump. |

|

Every Month |

|

Drain Tank, Flush Out and Remove Any Sediment. |

Check Fills If Clogged Due To Algae, Sediment / Salts, Etc. |

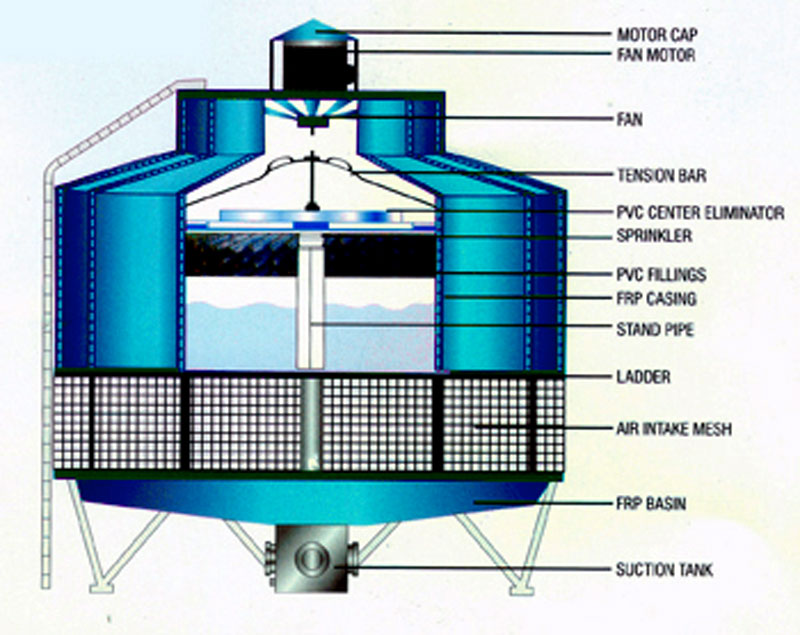

Check Structure / Frp Casing and Basin Damage and Repaired If Necessary. |

Clean From Outside With Soap and Water. |

Check And Tight All Bolts. |

Smear Bolts with Grease to Facilitate Easy Opening the Next Time. |

|

Every Six Months |

|

Grease All Bearings Of Motors. |

Grease All Bearings Of Sprinklers. |

Check Run out On Fan Motor Shaft. |

Clean Blades Of Foreign Matter. |

Check Fills If Damaged And Replace. |

Enlace Bearing Of Sprinkler Assembly After 2 Years And Fill With Grease. |